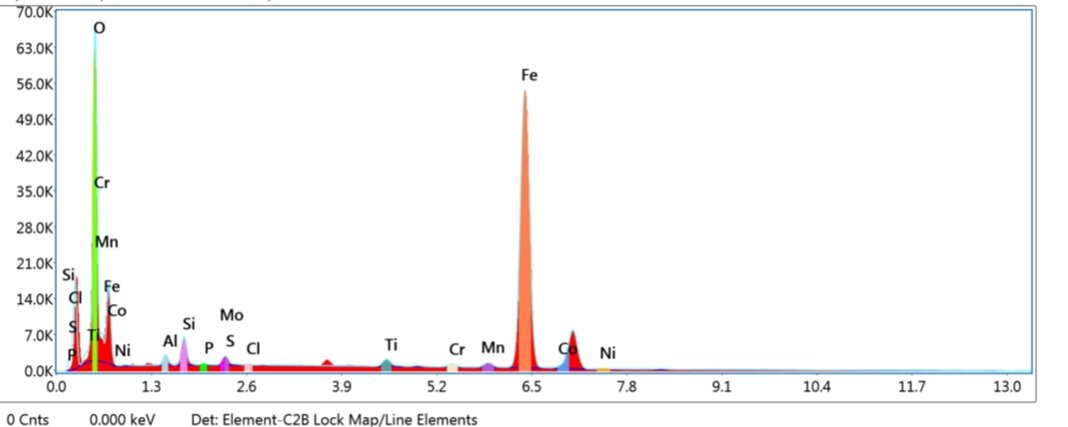

energy dispersive x-ray (EDS)

CHEMICAL ANALYSIS BY EDS

MES provides Energy Dispersive X-Ray (EDS) analysis for elemental composition of materials. EDS is a semi-quantitative x-ray technique used to identify the elemental composition of materials. Applications include particle identification, coating analysis, contaminant identification, and corrosion analysis.

The EDS lab silicon drift detectors are attachments to the Scanning Electron Microscopes (SEM). The imaging capability of the SEM identifies the specimen of interest, which can be instantly analyzed. The data generated by EDS consists of spectra showing peaks corresponding to the elements making up the true composition of the sample being analyzed. The speed of data collection combined with imaging of micro features makes EDS an ideal chemical analysis technique for forensic investigations.

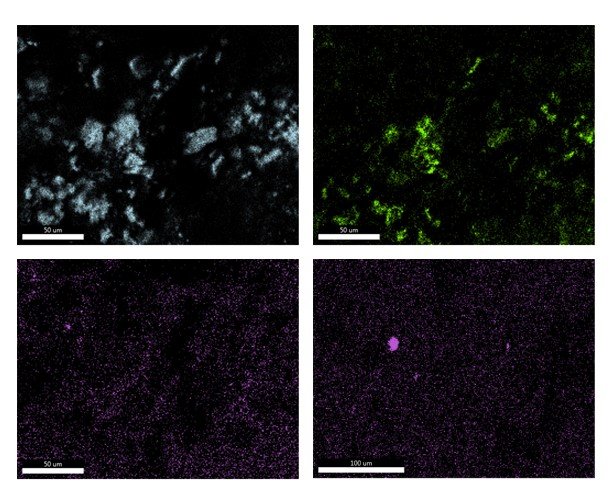

EDS SPECTRA & ELEMENTAL DOT MAPPING

EDS peaks are generated due to the fundamental principle that each element has a unique atomic structure, which produce a unique emission spectrum. Peak intensities can be semi-quantified to general a weight percentage breakdown for each element detected.

Elemental mapping of a sample and image analysis are also possible. The EDS analysis technique is non-destructive and specimens of interest can be examined with little or no sample preparation.

EDS Analysis Dot Map by Element

THE ADVANTAGEs of eds analysis

Energy Dispersive X-ray Spectroscopy (EDS) is a technique used in conjunction with scanning electron microscopy (SEM) that offers several benefits in materials analysis. Here are some of the key advantages of EDS:

Elemental Composition Analysis: EDS allows for the identification and quantitative analysis of elements present in a sample. It provides information about the elemental composition of the material, including both major and trace elements. This is particularly useful in determining the chemical makeup of unknown samples or identifying specific elements of interest.

Spatial Resolution: EDS can be performed alongside SEM, which provides high-resolution imaging of the sample surface. This combination allows for the correlation of elemental information with the sample's microstructure, morphology, and other surface features. It enables researchers to study the elemental distribution at specific locations within the sample, providing valuable insights into the material's structure and composition.

Non-Destructive Analysis: EDS is a non-destructive analytical technique, meaning it does not damage or alter the sample during analysis. It can be performed on a wide range of materials, including metals, ceramics, polymers, and minerals, without the need for complex sample preparation or destructive testing methods.

Wide Elemental Range: EDS can detect elements across the entire periodic table, from light elements such as hydrogen and carbon to heavy elements like uranium and lead. This broad elemental range makes EDS applicable to various fields, including metallurgy, geology, materials science, biology, and forensics.

Qualitative and Quantitative Analysis: EDS provides both qualitative and quantitative information about the elemental composition of a sample. Qualitatively, it identifies the presence of specific elements based on their characteristic X-ray emission spectra. Quantitatively, it determines the relative concentrations of elements, enabling percentage or weight fraction calculations.

Rapid Data Acquisition: EDS systems can quickly acquire elemental data from a sample, making it a fast and efficient technique for elemental analysis. Modern EDS detectors offer high count rates and improved sensitivity, allowing for shorter analysis times and enhanced data accuracy.

Elemental Mapping: With the integration of SEM, EDS enables elemental mapping of a sample's surface. By scanning the electron beam over the sample and collecting X-ray signals at each point, EDS can generate maps that illustrate the spatial distribution of elements. This technique is valuable in understanding elemental segregation, phase distribution, and identifying regions of interest within a sample.

Overall, the benefits of EDS make it a valuable tool for researchers and scientists in various fields, providing crucial elemental information, aiding in material characterization, and supporting the investigation of complex samples.

EDS CAPABILITIES

Qualitative and semi-quantitative elemental composition

Rapid identification of contaminants

Magnification – from 5x to 300,000x

Solid materials including metal, mineral and polymeric samples

Line Scan and Dot Mapping capability

EDS SPECIFICATIONS

ASTM E1508 - Elemental analysis by EDS

EDS SAMPLE REQUIREMENTS

Sample Size — up to 10 in. diameter and 3 in. in height.